ENM (GRP) Water Tank

- Water Tank Panel

- Watertightness, Drain Capability and Strength of Water Tank

- Reinforcement Structure

- Partition Type Water Tank

1. ENM (Earthquake Resistant) Water Tank Property

-

Excellent Insulation

- - Insulated panel with 4 layers structured & using Eco-friendly

Polyurethane heat insulating material ensure excellent insulati effect

-

Easy to clean & Excellent hygienic

- - Because of wide manhole, it is easy to clean inside of water tank & it has excellent hygienic & watertightness

-

Excellent durability

- - It secures excellent surface strength & durability as Using high-temperature & high pressure press machine (2,500 Ton)

-

Competitive Price

- - Excellent price competitiveness & High quality Water tank with no tie-rod type

-

Easy & quick to install

- - It is easy and quick to install with easy assembly of upper & lower panels

-

Structure of Non Skid base

- - Excellent Earthquake-resistant without concrete frame & skid base.

2. ENM Water Tank Item Name Code and Form

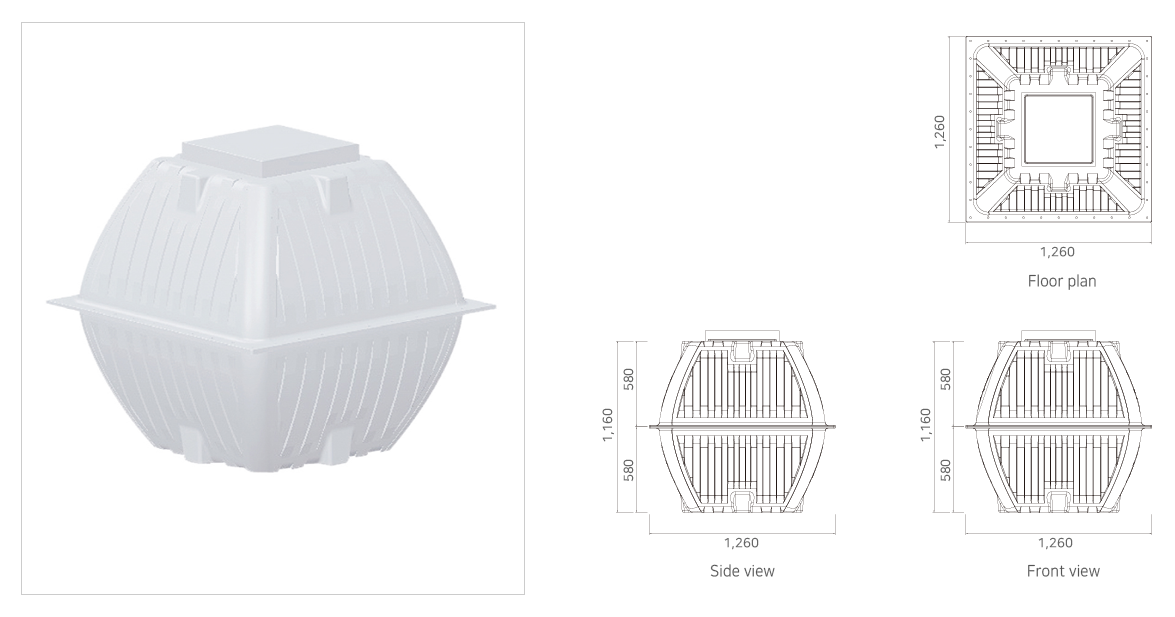

ENM (GRP) 1㎥ TYPE (5㎡)

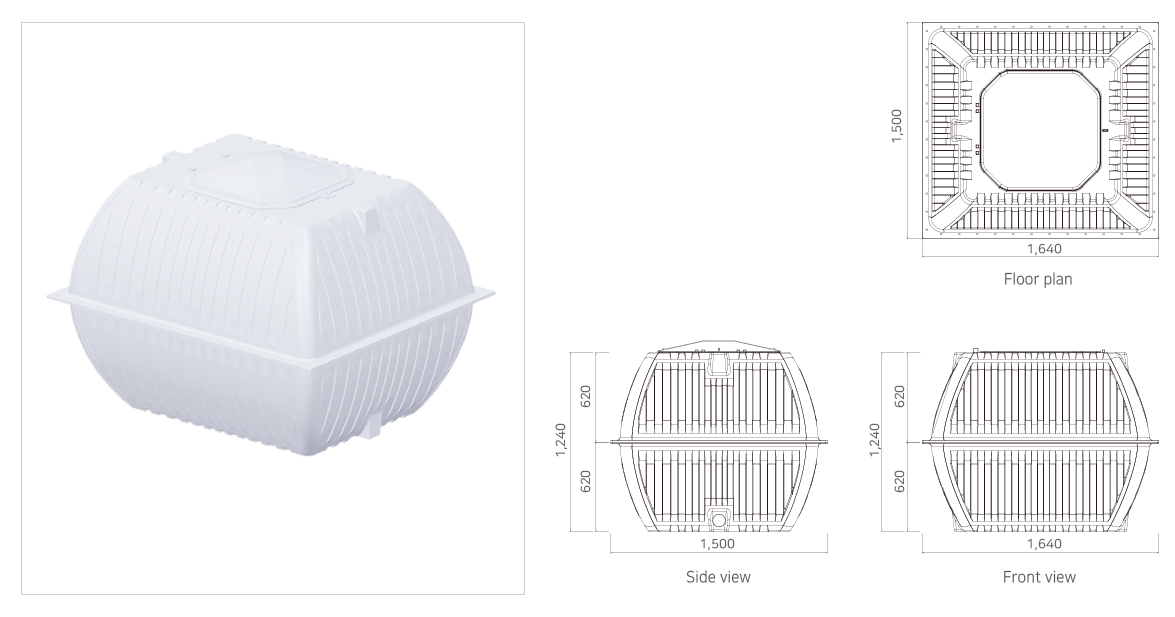

ENM (GRP) 2㎥ TYPE (8㎡)

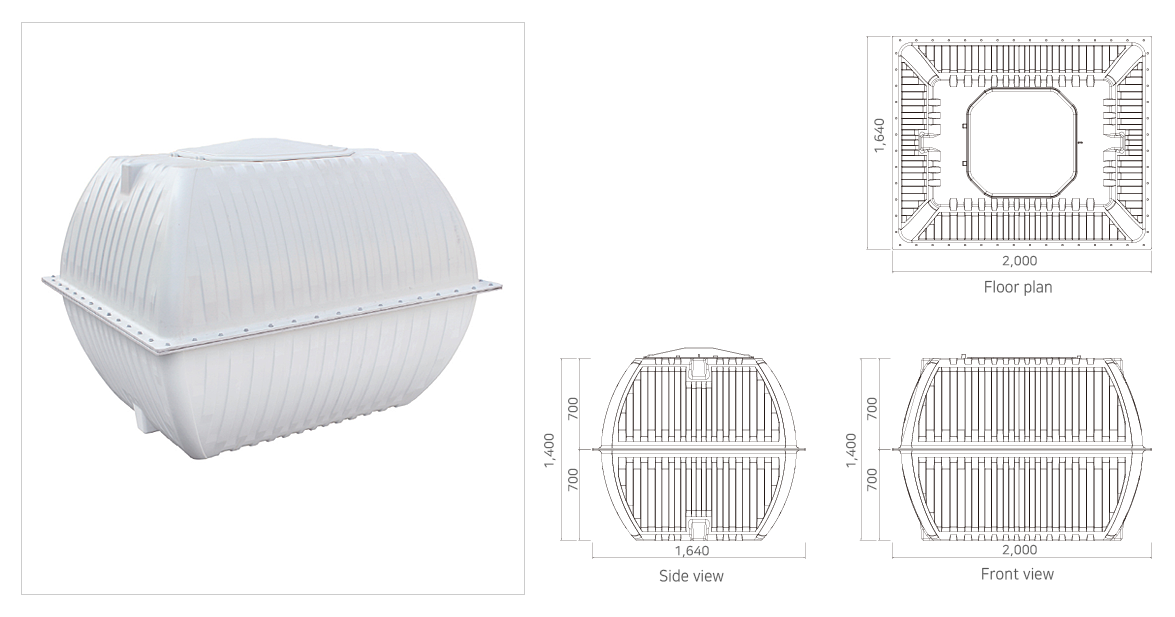

ENM (GRP) 3㎥ TYPE (10㎡)

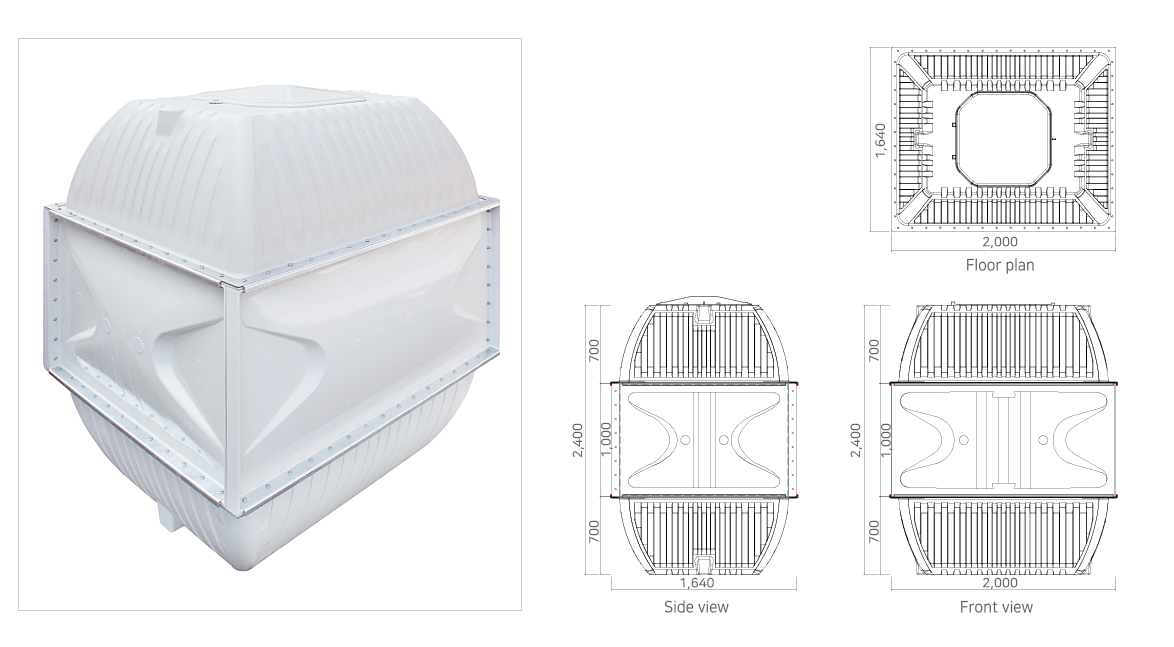

ENM (GRP) 5㎥ TYPE (14㎡)

ENM (GRP) 6㎥ TYPE (17㎡)

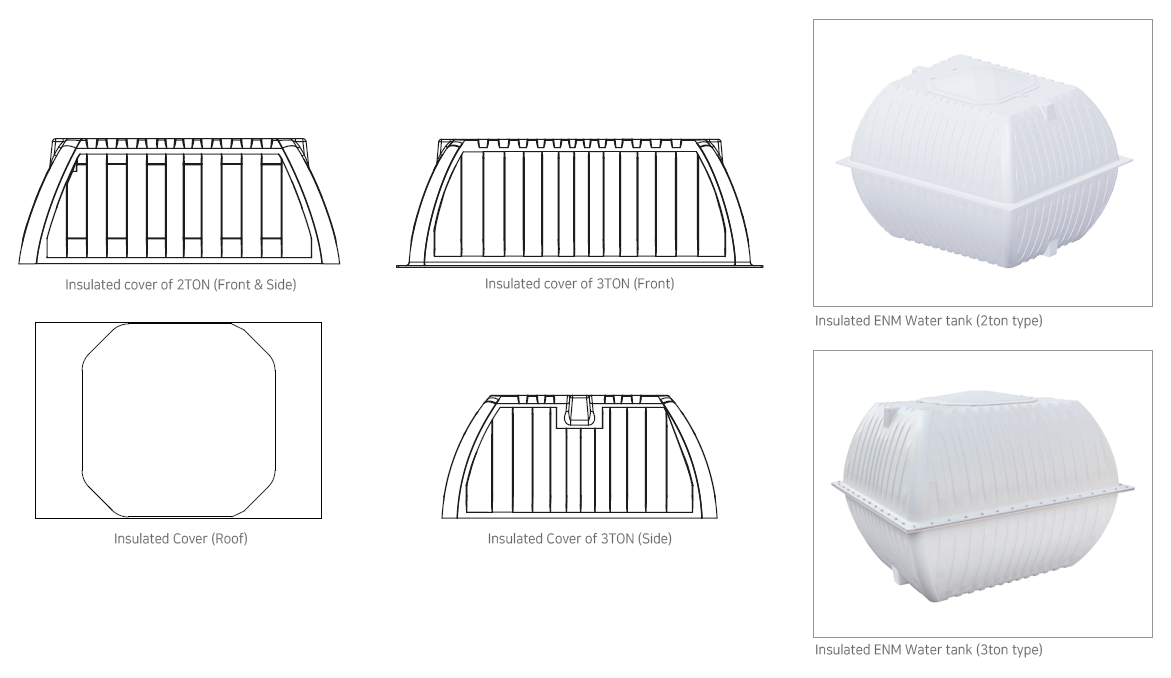

3. Type & Shape of ENM Insulated panel

4. Assembly of Insulated panel

-

ⓐ Applying glue on Insulated cover with urethane foaming

ⓑ Applying glue on ENM Water Tank Panel which installation is complete.

ⓒ Glue to dry : About 7 minutes at room temperature, around 30℃,

About 12 minutes at room temperature, around 15℃.

-

ⓓ Putting the dried Insulated cover on ENM Panel which applied glue.

ⓔ Applying silicone on the edge of Insulated cover.

ⓕ Assembly of inlet, outlet, Socket etc.